- In a world increasingly driven by technology, these humble household essentials remind us of the importance of simplicity and functionality. The cosulet, with its nostalgic charm, and the bulb, symbolizing progress, coexist harmoniously in our lives, each contributing its unique essence. As we continue to innovate and advance, let us not forget the value these everyday objects hold and the roles they play in shaping our daily experiences.

The process of manufacturing aluminium window profiles involves several steps, from raw material selection to final product testing. Here is an overview of the typical process:

- The origin of the metal box with a padlock can be traced back to ancient times when people needed a way to protect their valuable possessions from theft and intrusion. The use of metal as a material for the box provided durability and strength, while the addition of a padlock added an extra layer of protection by requiring a key for access.

- Moreover, aluminium window profile manufacturers often provide custom solutions, working closely with architects and builders to create bespoke designs that align with specific project requirements. Their products not only cater to residential buildings but also find extensive use in commercial and industrial settings due to their strength, low maintenance, and recyclability.

This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments

This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments This diagnostic phase is critical as it ensures that the correct solution is provided, whether it involves simple roller replacement or more complex track alignments sliding door roller replacement inc.

sliding door roller replacement inc.Aluminum profiles offer significant advantages in window construction due to their numerous benefits:

One of the key benefits of using a stainless steel gate lock box is the high level of security they provide. Made from strong and resistant materials, these lock boxes are extremely difficult to tamper with, making it nearly impossible for intruders to break into your property. This added security gives you peace of mind knowing that your property and belongings are safe and secure.

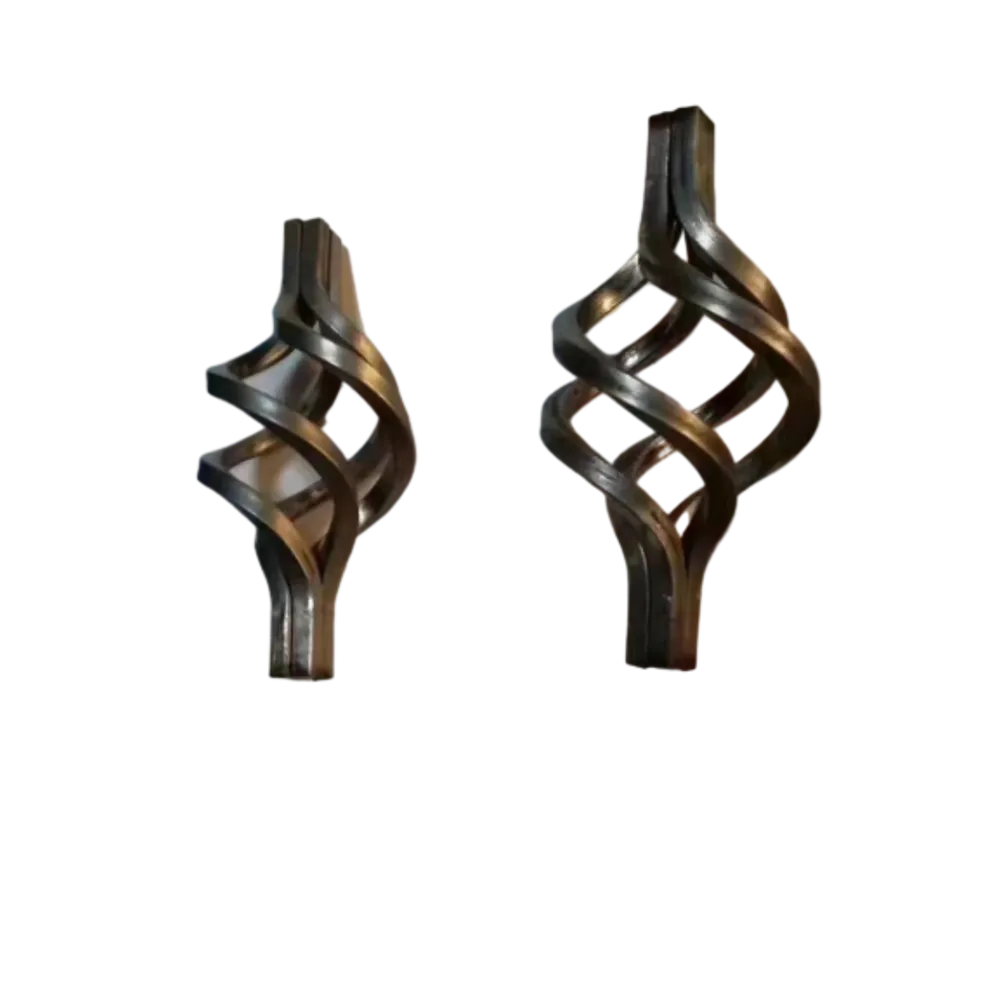

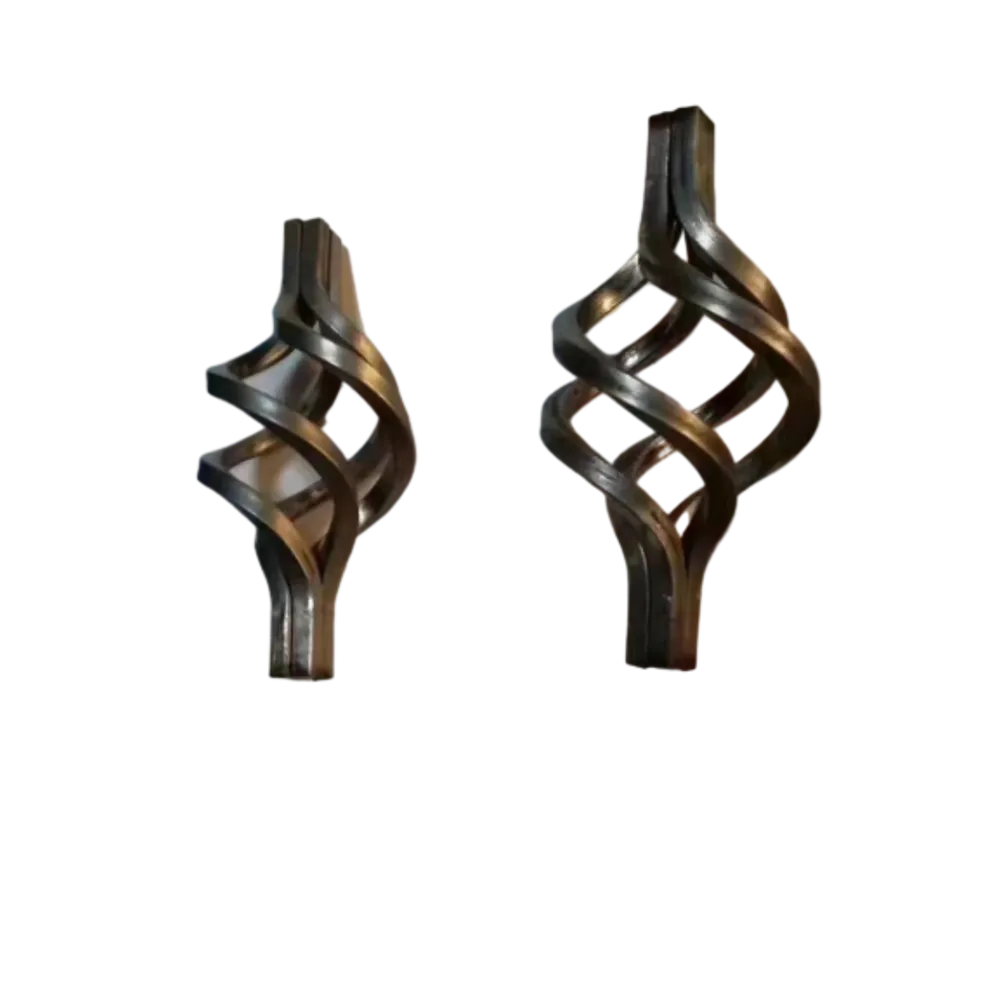

The versatility of cast iron panels allows them to be integrated into various design aesthetics, from traditional to contemporary. Whether used in a historic restoration project or as a statement piece in a modern build, these panels add depth and texture to any space. Moreover, their modular nature makes them an excellent choice for custom installations, allowing homeowners and designers to create personalized designs that reflect unique tastes.

ornamental cast iron panels

The Importance of Steel Security Safe Lock Boxes

However, the exact cost of the fencing will depend on a number of factors, including design complexity, size, and the specific needs of the installation site.

Bottom hung windows opening inwards

One of the main advantages of working with cast iron is its durability and strength. Ornamental cast iron pieces are able to withstand the elements and last for many years without deteriorating. This makes them an ideal choice for outdoor applications such as fences, gates, and railings.

There are letters, some yellowed with age, their handwriting a testament to past connections, to friendships and loves that have shaped me There are letters, some yellowed with age, their handwriting a testament to past connections, to friendships and loves that have shaped me

There are letters, some yellowed with age, their handwriting a testament to past connections, to friendships and loves that have shaped me There are letters, some yellowed with age, their handwriting a testament to past connections, to friendships and loves that have shaped me small metal storage box with lock.

small metal storage box with lock.Fortune Aluminum, a Chinese manufacturer with more than 20 years of expertise in aluminum extrusion. Trust us, choose us, and we will work with you to build a better life and a brighter tomorrow.

When it comes to the aesthetics and functionality of our homes, window and door fittings play a crucial role. These fittings not only enhance the visual appeal of our living spaces but also contribute significantly to security, energy efficiency, and overall convenience. Understanding the various types of window and door fittings and their importance can help homeowners make informed choices that elevate their living experience.

One of the most frequent questions I get as a fence designer is whether to install either a wrought iron or aluminum fence. Both are great fencing materials and both will do the job of providing a highly secure perimeter for your home or commercial property. However, there are some distinct differences between the two fence materials worth considering before making a final decision. I hope that this explanation of their differences will help!

In a nutshell, the main difference between these two types of surface finish is the oxide layer. Anodized finish has a layer of oxide, whereas mill finish does not have the oxide layer.